-

Photonics LAB

The Photonics Laboratory

The Photonics Laboratory introduces itself

-

education

For Students

Here students will find all relevant information

-

Research

Research

Current research projects of the Photonics Laboratory

-

cooperation

Industry

For coopertion partners

-

Contact

Contact

How to reach us

Munich University of Applied Sciences Department Of Applied Sciences And Mechatronics

Equipment of the Photonics Laboratory

The Photonics Laboratory has established a wide range of high level equipment for various fiber sensing applications, including fiber processing, fiber Bragg grating (FBG) manufacturing and calibration devices.

FBG Manufacturing

|

Laser source: |

|

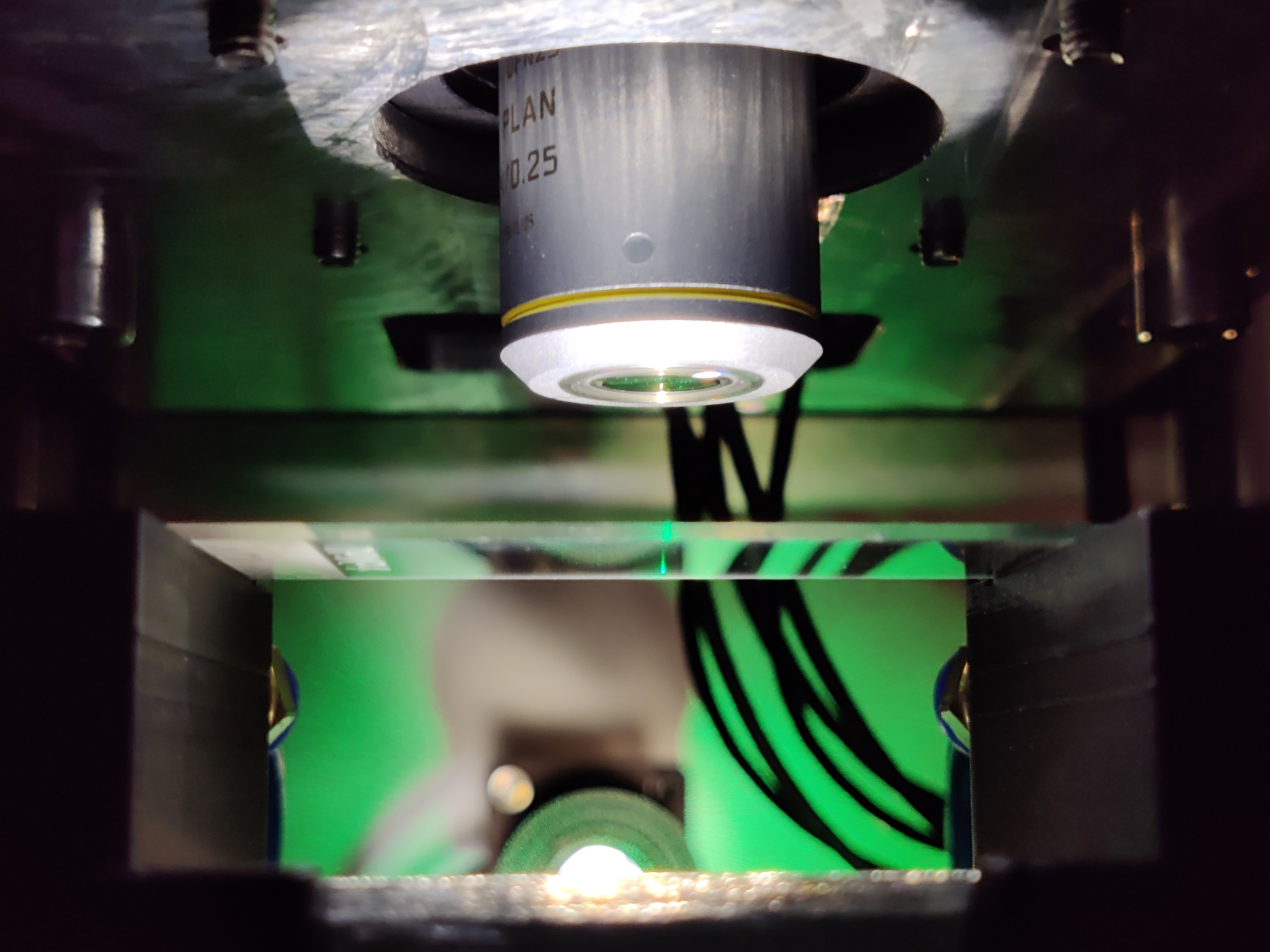

Ultrafast laser workstation for material processing of transparent media Ultrafast laser source and high precision positioning system

|

|

|

Laser source: |

|

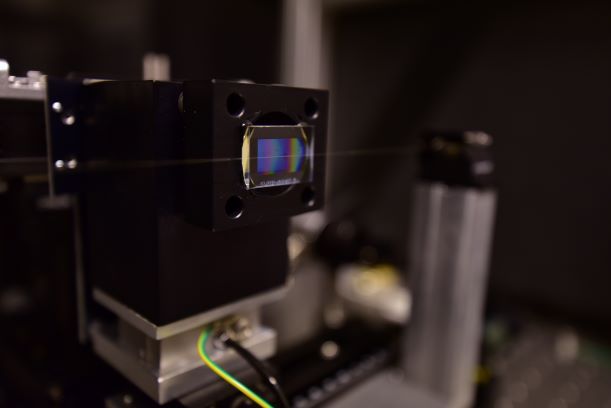

FBG Inscription Facilities Excimer-laser at 248 nm and phase mask technique

|

|

|

High pressure hydrogen chamber: |

|

Hydrogen Loading Facility High pressure hydrogen chamber

|

|

FBG Calibration

|

Four point bending setup: |

|

Strain Calibration Facility Four point bending: -1000 µstrain to 1000 µstrain

|

|

|

Hydrogen calibration facility: |

|

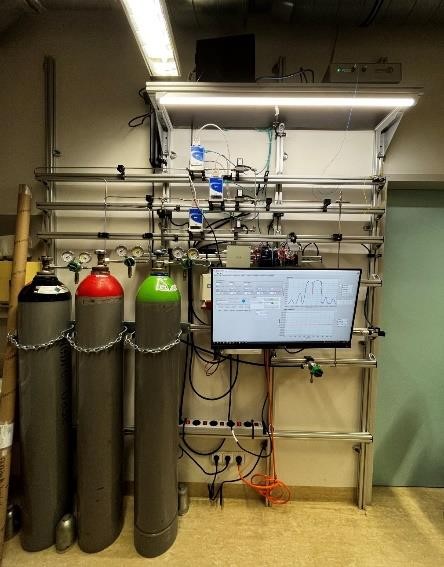

Hydrogen Calibration Custom-built hydrogen calibration below 2 vol. %

|

|

|

High temperature furnace: |

|

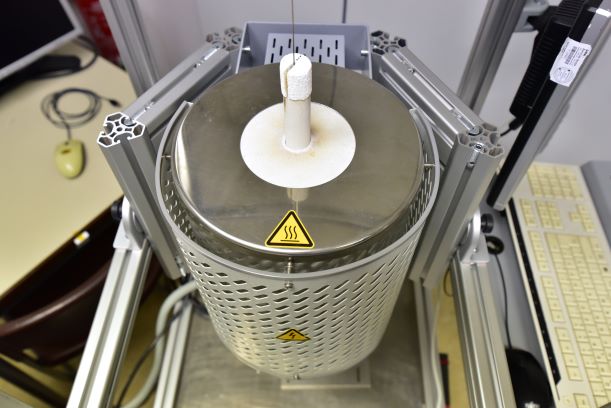

Temperature Calibration Several furnaces with a total temperature range between -40°C and 1200°C

|

|

FBG Evaluation

|

Interrogator, |

|

FBG Interrogation Scanning laser systems (FBG wavelength multiplexing)

|

|

|

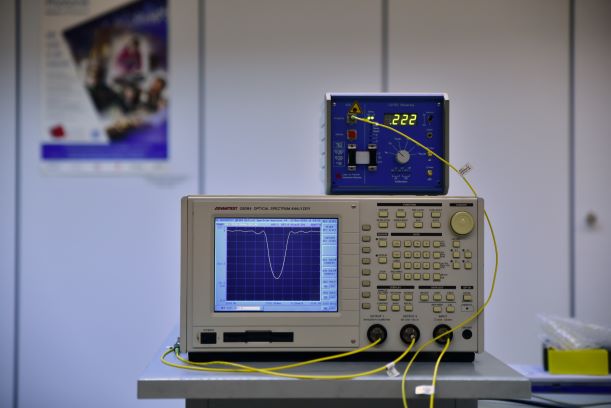

Optical spectrum analyzer: |

|

Spectral Analysis Optical spectrum analyzer

|

|

Fiber Processing and Testing

|

Filament Splicing Unit: |

|

Fiber Splicing, Cleaving and Recoating Arc-charge and filament splicing units

|

|

|

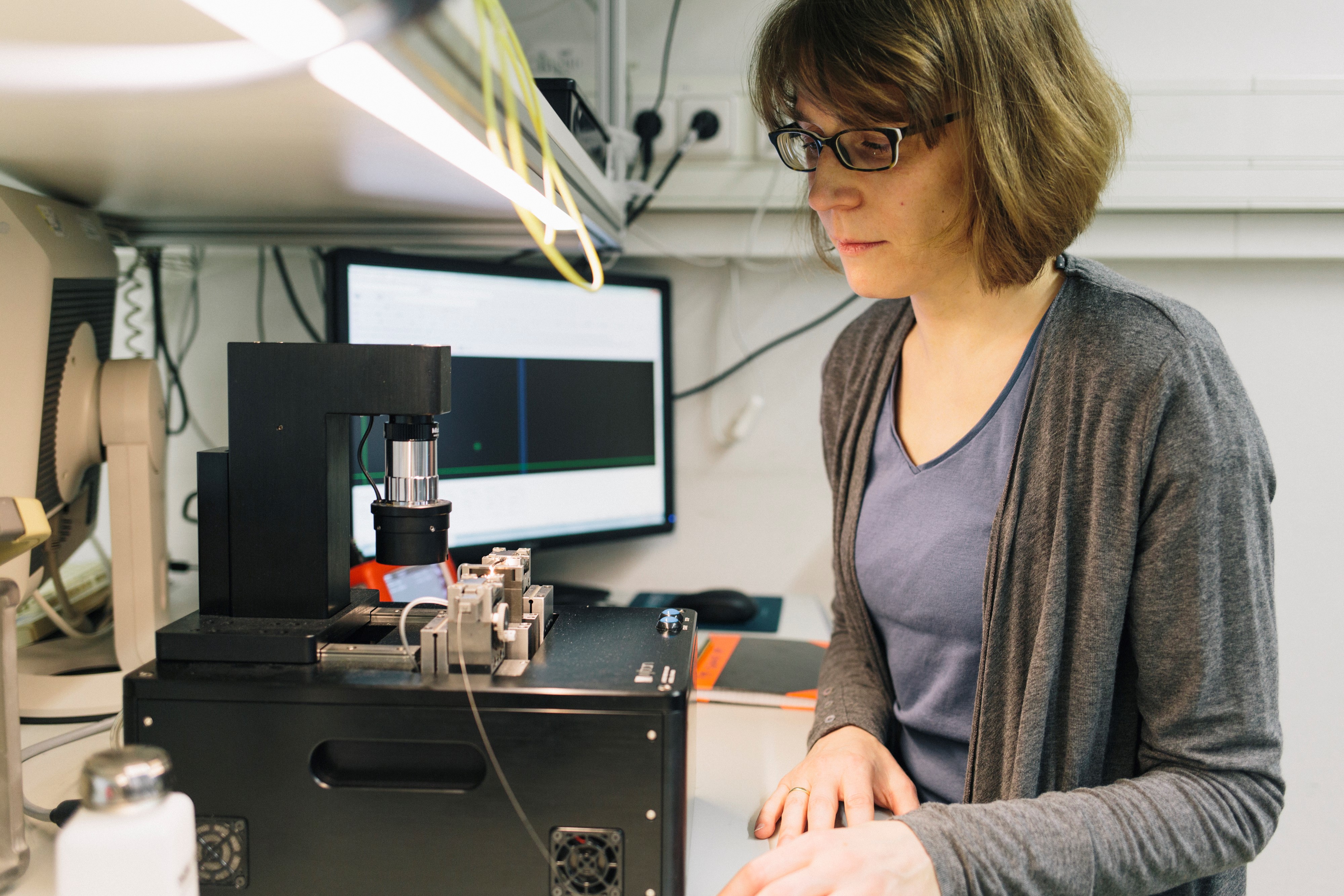

Fibers |

|

Fiber Testing Optical and mechanical fiber characteristics

|

|

|

Coupler Workstation |

|

Fiber Coupler Development and Fabrication Forging tool for fiber optics

|

|