|

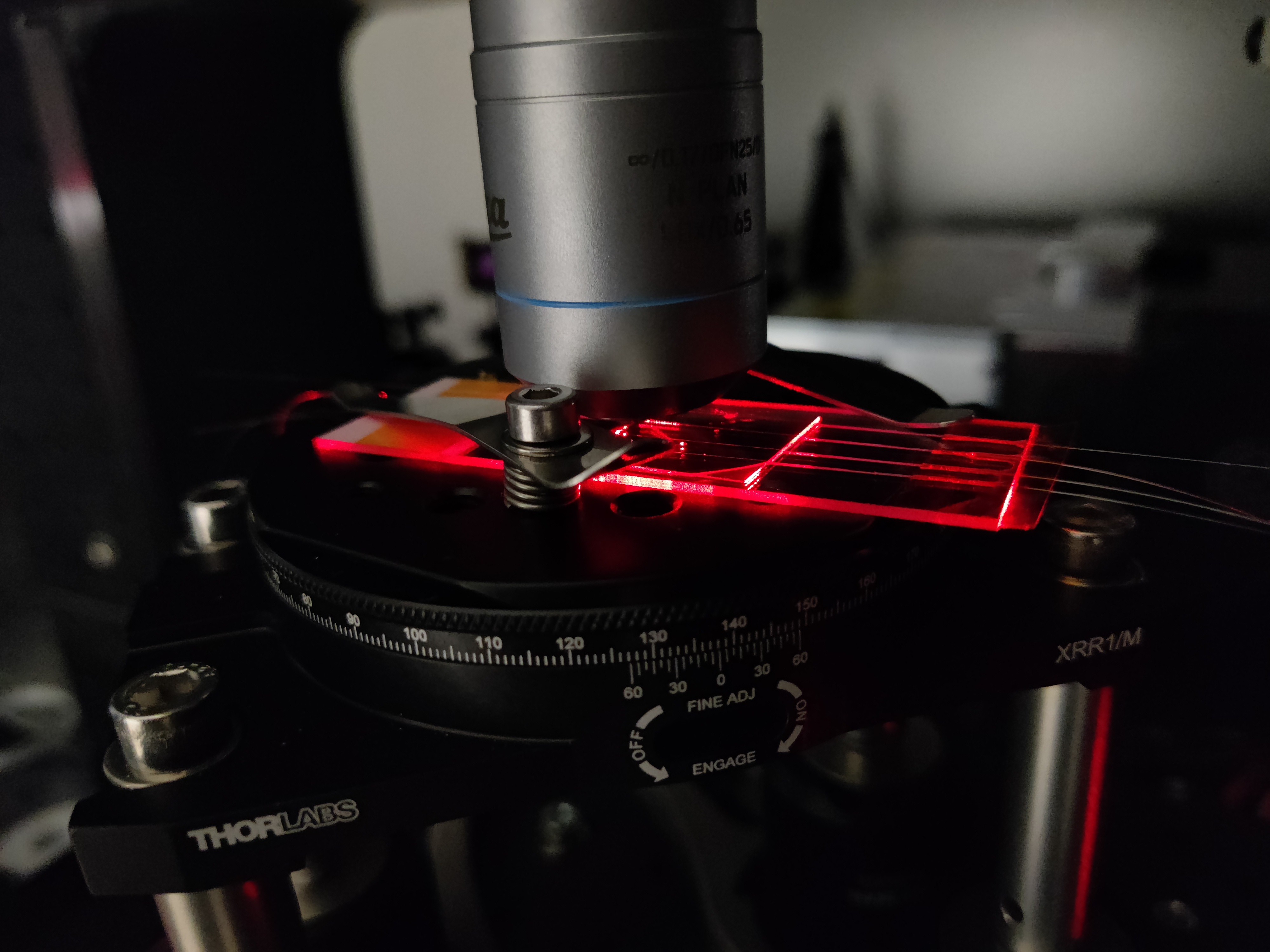

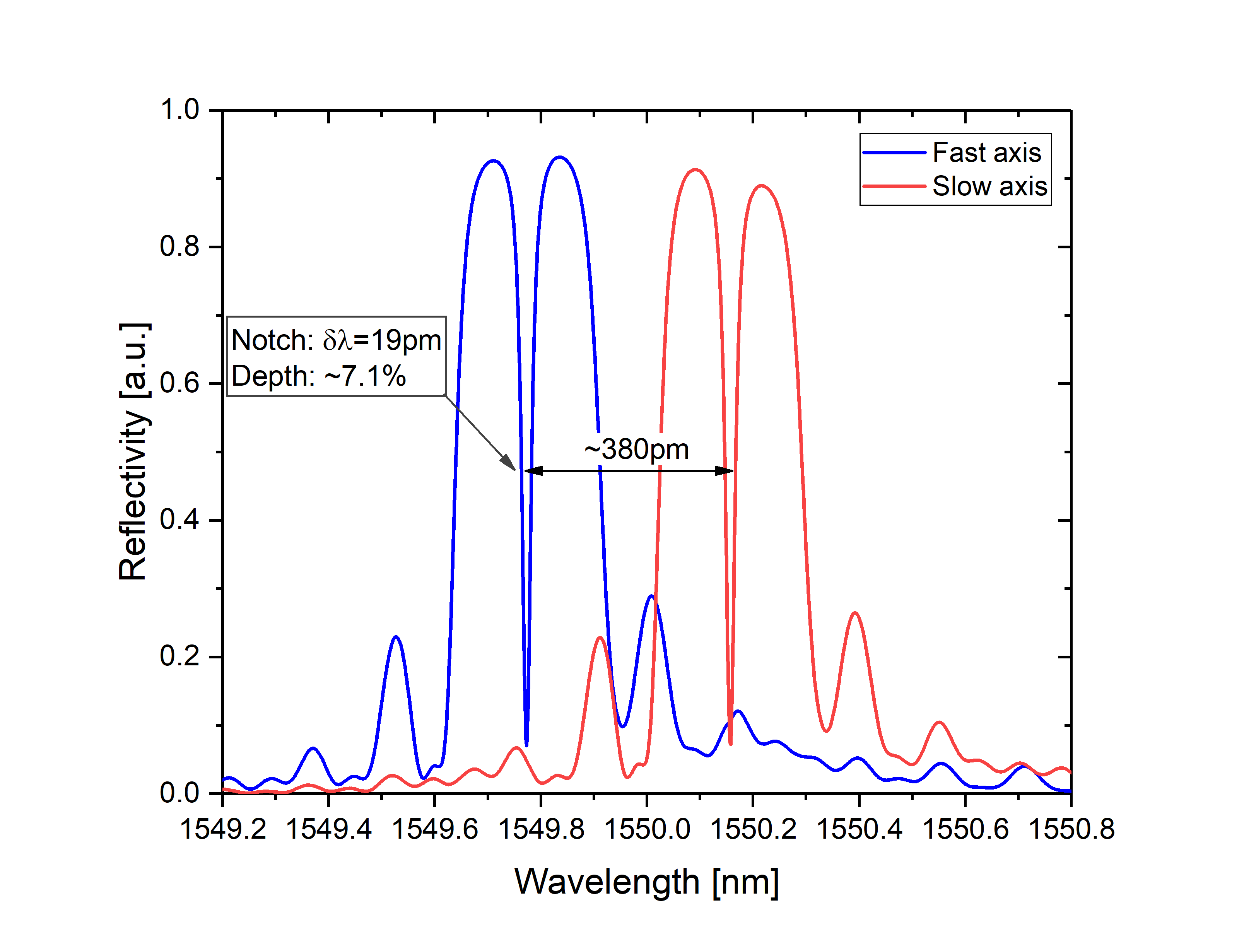

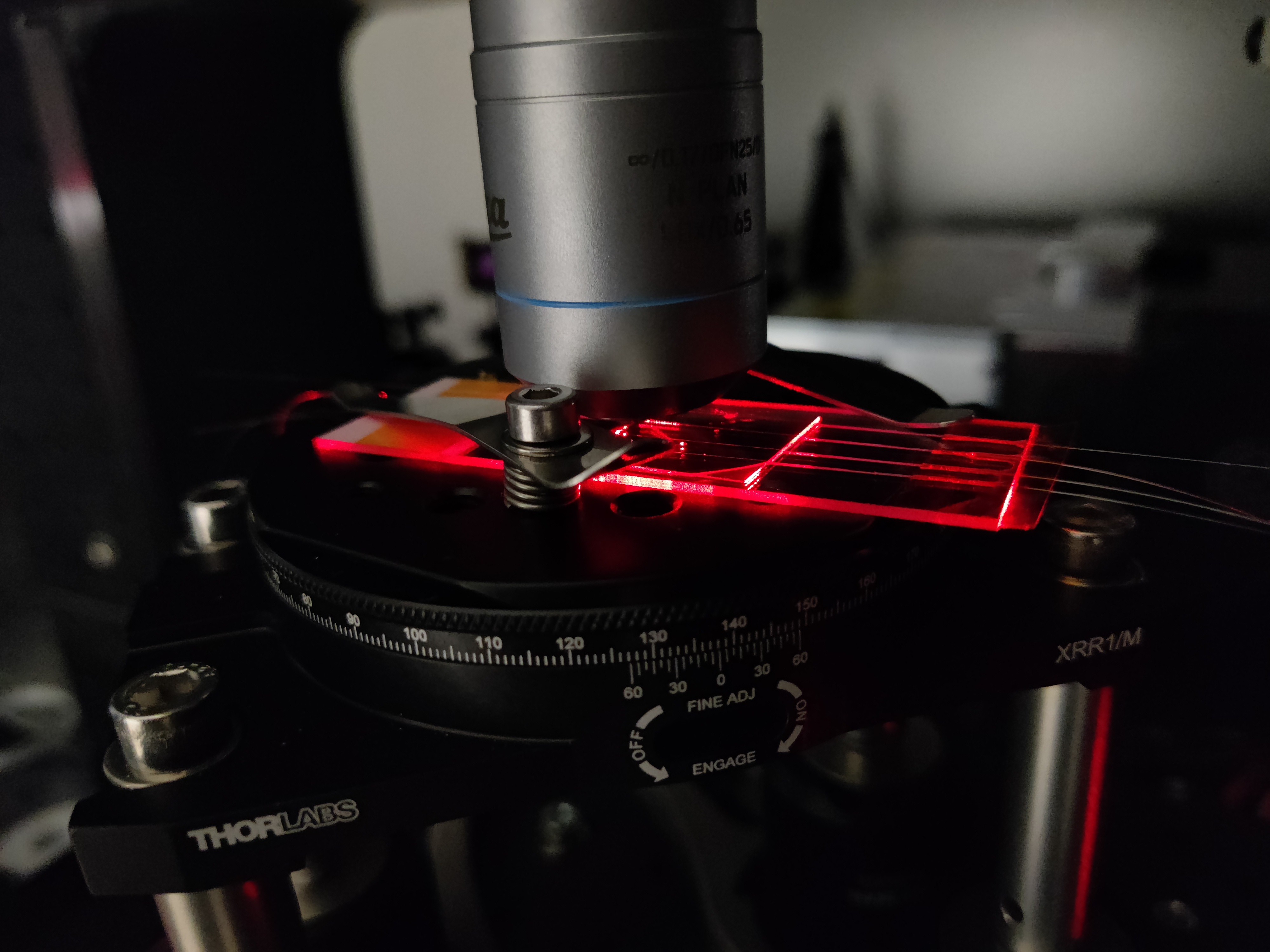

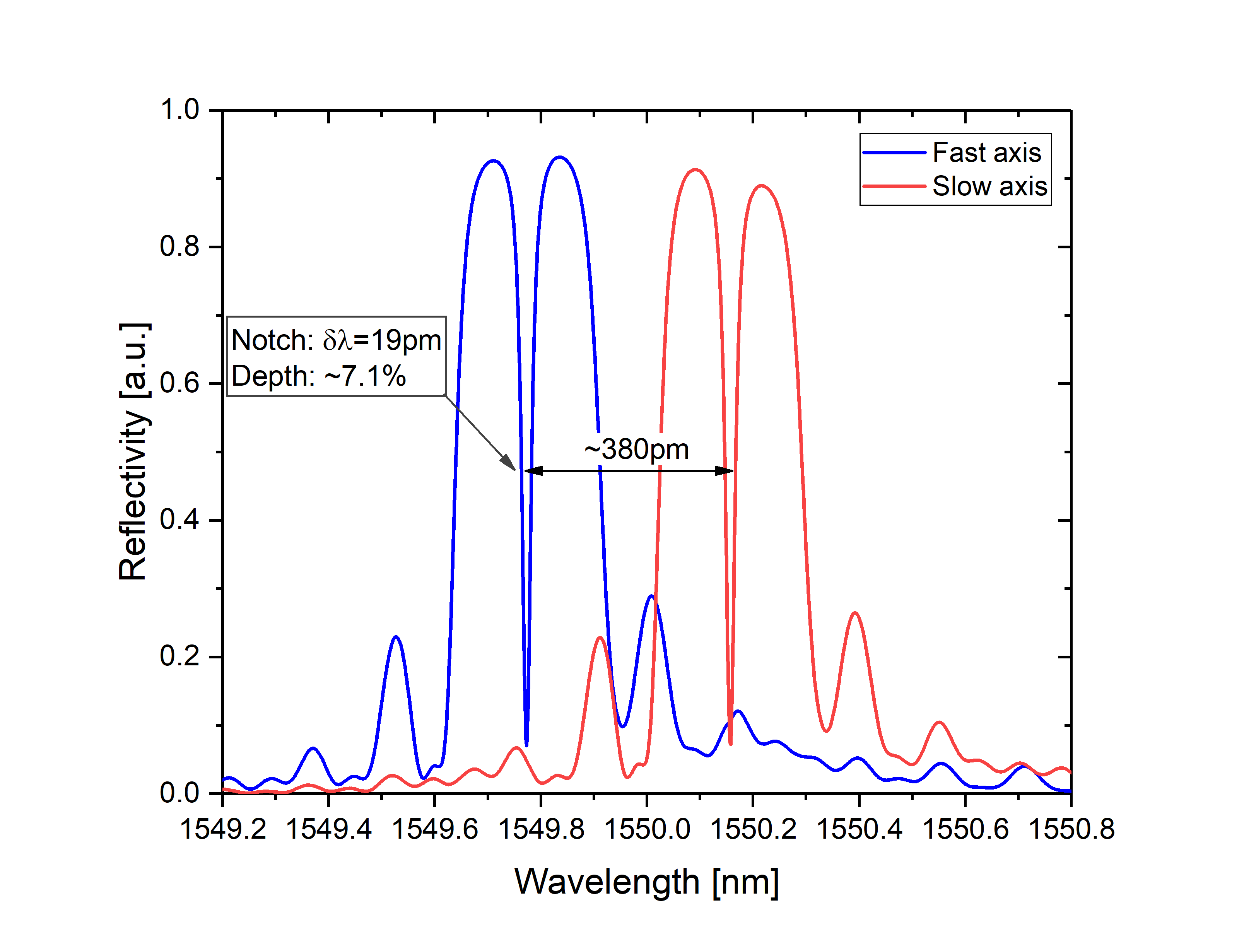

Fibre Bragg gratings for random Raman lasers

Funding:

This Project is supported by the Federal Ministry for Economic Affairs and Climate Action (BMWK) on the basis of a decision by the German Bundestag.

|

|

|

Fiber Bragg Gratings for Improved Fibre Lasers

Period: 2024-2026

Titel: Improvement of the direct writing technology of fiber Bragg gratings for the use in high-power sources with adjustable wavelengths for quantum technology

Abstract: Key part of the research project are random Raman fiber lasers (RRFL), which represent innovative components of a new laser platform. In order to achieve wavelength flexibility of the RRFL, the FBG direct writing process is to be further improved and upgraded for the production of the wavelength-determining elements in the RRFL.

Partners:

|

Toptica Projects

|

|

|

|

Multi-parameter optical hydrogen sensing with in-situ temperature compensation

Funding:

Deutsche Forschungs- Gemeinschaft (DFG)

Grant number: 448330062

|

|

|

Multiparameter Low-Level Optical Hydrogen Sensing

Period: 2021-2026

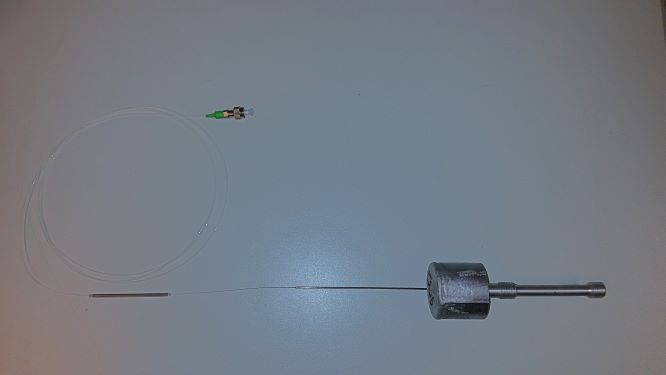

Titel: Function-optimized fiber optic sensing for the detection of low hydrogen levels with structured, palladium coated pi-shifted fiber Bragg gratings

Abstract: Palladium (Pd) has a unique hydrogen selectivity and expands as hydrogen diffuses into the material, which is coated on optical fibers. Transducing strain to the optical fiber, while the Pd expands and simultaneously monitoring the strain with temperature-decoupled high-precision pi-shifted fiber Bragg gratings enables spark-free, mostly inherent, and EM-resistant hydrogen detection on ppm-scale.

Partners:

|

Wuhan University of Technology

|

|

|

|

|

|

|

Completed Projects

| |

|

InnoTurbinE

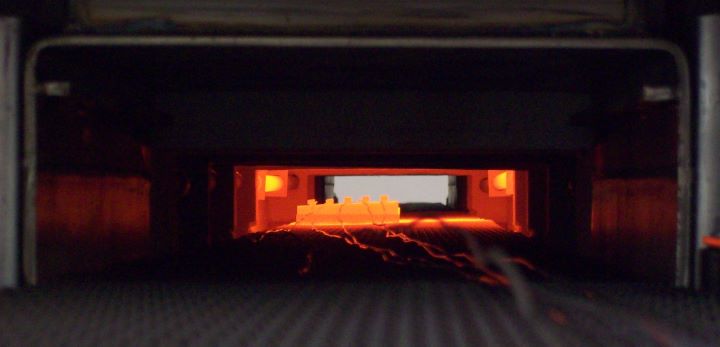

Compressor of an engine (MTU Aero Engines AG)

Funding:

MTU Aero Engines AG

Federal Ministry for Economic Affairs and Energy

|

|

|

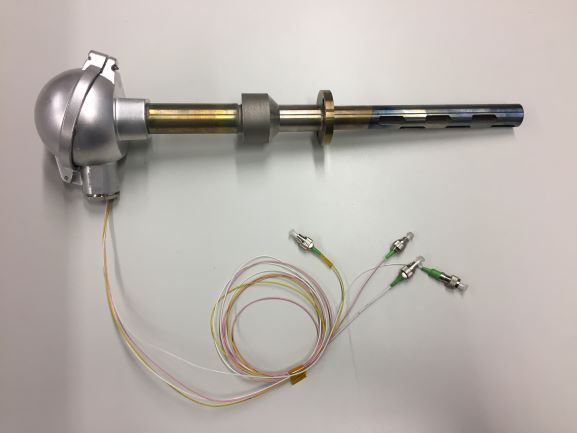

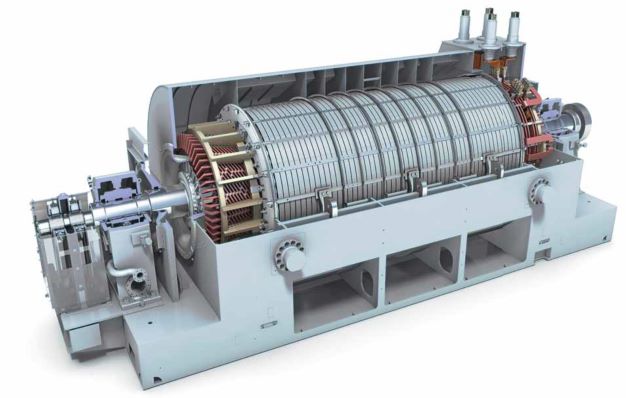

InnoTurbinE

Period: 2020-2024

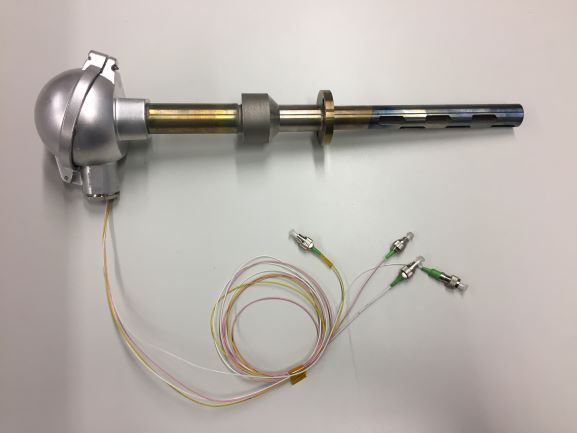

Titel: Innovative turbomachinery for sustainable energy systems. Subproject: Fiber optic probes for high temperature measurements in gas duct

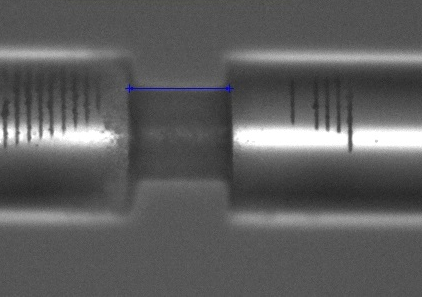

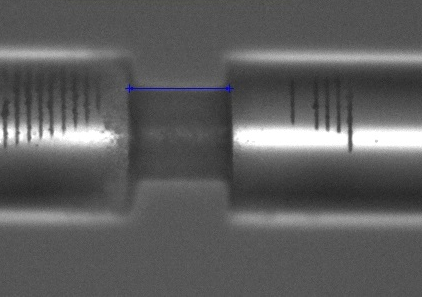

Abstract: Regenerated fiber Bragg gratings are used to measure a total temperature profile with a high spatial density in a turbine. The measuring point density shall be increased by reducing the RFBG length down to ≤1mm and the distance down to ≤2mm. Read more

Partners:

|

MTU Aero Engines AG

|

|

|

AG Turbo

(RWTH Aachen, TU Berlin, TU Dresden, Universität Duisburg-Essen, Leibniz Universität Hannover, TU München, Universität Stuttgart, Deutsches Zentrum für Luft- und Raumfahrt e.V., MAN Energy Solutions SE, MTU Aero Engines AG, Rolls Royce Deutschland Ltd & Co. KG, Siemens Energy Global GmbH & Co. KG)

|

|

|

|

|

Pi-LMFBG

Funding:

Zentrum zur Forschungsförderung und wissenschaftlichen Nachwuchs (FORWIN),

Munich University of Applied Sciences

|

|

|

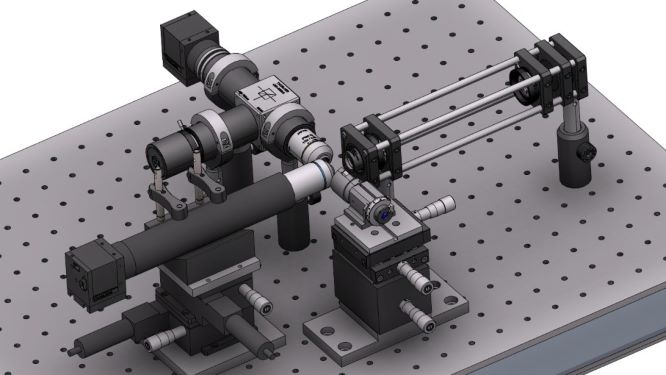

Laserstructured Force Sensor (Pi-LMFBG)

Period: 2019-2020

Titel: Highly sensitive fiber optical force sensor based on a fs-laser structured fiber Bragg grating (FBG)

Abstract: The development and evaluation of sensor elements that were fabricated with two different laser material processing techniques. They combine the advantages of pi-shifted FBGs within the fiber core with a micro-structured cladding for an enhanced force sensitivity.

Partners:

Laser Center, Department of Applied Sciences and Mechatronics, Munich University of Applied Sciences

|

|

|

|

|

Temperature distribution monitoring in SOC-Stacks

Funding:

Forschungszentrum Jülich GmbH

|

|

|

High temperature monitoring in solid oxide fuel cell

Period: 2022-2023

Titel: Measurement of Temperature Distribution in Solid Oxide Cell-Stacks

Abstract: Solid Oxide Cells (SOC) are electrochemical energy converters with an oxide-ceramic solid electrolyte that typically operate at high temperatures to achieve high efficiencies. The temperature distribution in a SOC stack has so far been difficult to measure due to the stack construction and the high temperatures (650-850 °C). Due to the merits of small size, high sensitivity, immunity to electromagnetic interference, the capacity to achieve quasi-distributed sensing, and the high-temperature resistance, regenerated fiber Bragg gratings (RFBGs) are chosen to measure the temperature distribution inside SOC. Just in one fiber, multipoint RFBG temperature sensors array were fabricated and inserted into SOC-Stacks for monitoring the temperature distribution during different working conditions of SOC.

Partners:

|

IEK-9, Institute of Energy and Climate Research , Forschungszentrum Jülich GmbH

|

|

|

|

|

|

FBG-Aluguss

Funding:

Deutsche Forschungs- Gemeinschaft (DFG)

Grant number: RO 4145/3-2

|

|

|

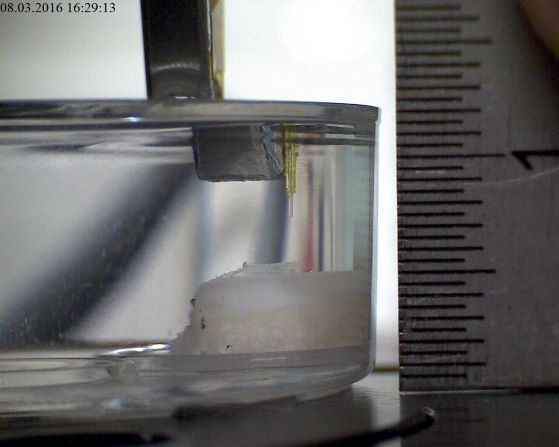

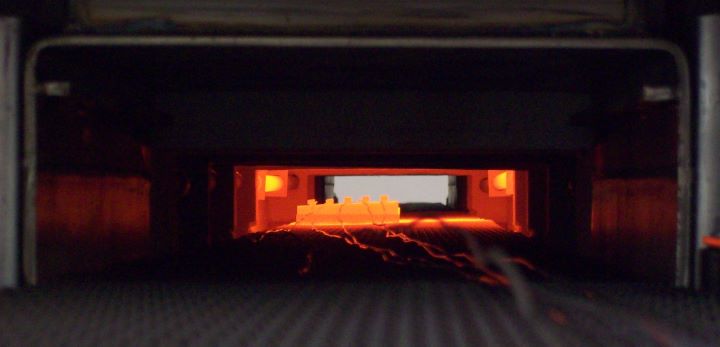

Strain Measurement in Aluminum Alloys (FBG-Aluguss)

Period: 2018-2020 (Follow-up project)

Titel: In situ strain measurement during solidification and cooling of aluminum alloys using regenerated fiber Bragg gratings

Abstract: High temperature stable regenerated fiber Bragg gratings (RFBGs) are used to measure temperature and strain at different locations during the casting process of aluminum. After the casted parts cooled down, the already embedded RFBGs are used as integrated sensors to monitor loads during operation.

Partners:

Institute for Measurement Systems and Sensor Technology, Department of Electrical and Computer Engineering, Technical University Munich

Chair of Metal Forming and Casting, Department of Mechanical Engineering, Technical University Munich

|

|

|

|

|

High-Temp-Net

Funding:

Bayerische Forschungs-stiftung (BFS)

Grant number: AZ-1146-14

|

|

|

Fiber Optic High-Temperature Network (High Temp Net)

Period: 2015-2019

Titel: Fibre-optic high-temperature sensor network for improving the efficiency of gas turbines and reactors in the process industry

Abstract: Multiplexing of regenerated fiber Bragg gratings allows temperature measurements up to 800°C with high spatial resolution at minimum cross-sections. Here, this technology is used to measure temperature distributions in chemical reactors and in the exhaust duct of gas turbines,

read more in German.

Partners:

MAN Energy Solutions SE

Siemens AG, Corporate Technology

|

|

|

|

|

Indentation

Funding:

Deutsche Forschungs- Gemeinschaft (DFG)

Grant number: RO 4145/4-1

|

|

|

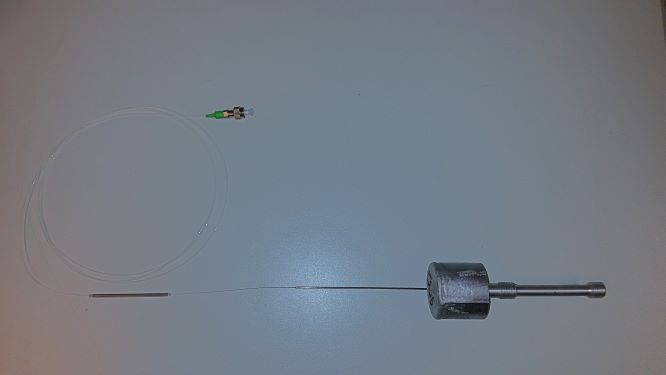

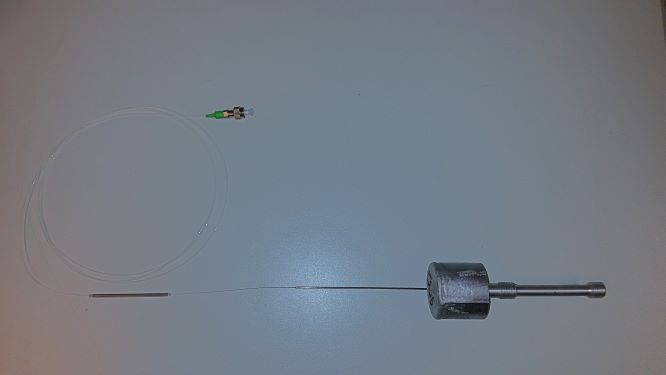

Arthrosis Diagnostics with FBG-Indentation (Indentation)

Period: 2016-2019

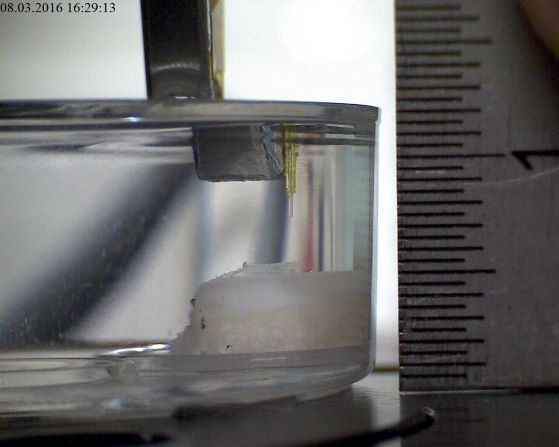

Titel: Innovative arthrosis diagnostics with fiber Bragg grating based indentation suitable for endoscopic examinations

Abstract: The development of a micro-indenter system, which contains an FBG-based force sensor is intended to help surgeons to localize osteoarthritic. The dimensions in this novel setup are significantly smaller than all previous indentation devices and feasible to be integrated in an arthroscope. The research aim is to validate the concept on in vitro healthy and degenerated cartilage samples.

Partners:

Laboratory of Experimental Surgery and Regenerative Medicine, Clinic for General, Trauma and Reconstructive Surgery, Ludwig Maximilian University Munich

Nanoanalitics and Biophysics Laboratory, Department of Applied Sciences and Mechatronics, Munich University of Applied Sciences

|

|

|

|

|

|

FBG-Aluguss

Funding:

Deutsche Forschungs- Gemeinschaft (DFG)

Grant number: RO 4145/3-1

|

|

|

Strain Measurement in Aluminum Alloys (FBG-Aluguss)

Period: 2015-2018

Titel: In situ strain measurement during solidification and cooling of aluminum alloys using regenerated fiber Bragg gratings

Abstract: High temperature stable regenerated fiber Bragg gratings (RFBGs) are used to measure temperature and strain at different locations during the casting process of aluminum. After the casted parts cooled down, the already embedded RFBGs are used as integrated sensors to monitor loads during operation.

Partners:

Institute for Measurement Systems and Sensor Technology,Technical University Munich

Chair of Metal Forming and Casting, Technical University Munich

|

|

|

|

|

|

HiBi-Powerplant

Funding:

Bundesministerium für Bildung und Forschung (BMBF)

Grant number: 03FH055PX3

|

|

|

Fiber Optical Sensor System for Generators (Powerplant)

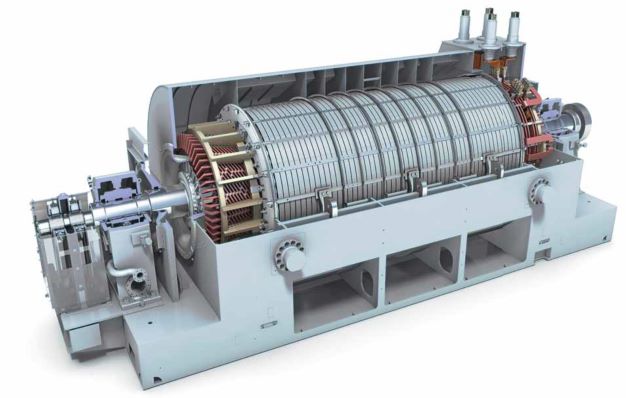

Period: 2014-2018

Titel: Fiber optical HiBi-FBG sensor system for increasing the efficiency in the utilization of high power generators

Abstract: The development of a FBG-based sensor system that allow strain compensated temperature measurements within high power generators is the main goal of this project. The focus lies on the utilization of surface-attached polarization maintaining fibers for the compensation of transversal strains while measuring temperature and longitudinal strains on the FBG sensor element.

Partners:

Siemens AG, Corporate Technology

|

|

|

|

|

|

|

|

High-Temp

Funding:

Bundesministerium für Bildung und Forschung (BMBF)

Grant number: 170 10X11

|

|

|

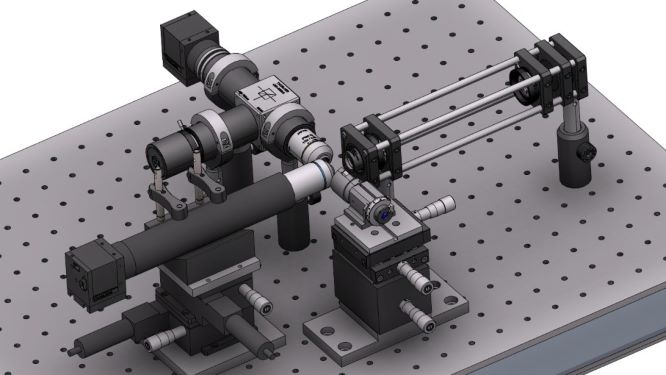

High Temperature FBG for Process Control (High Temp)

Period: 2011-2015

Titel: High temperature resistant fiber optical temperature sensors in the process and condition monitoring

Abstract: Regenerated FBGs have been developed for high temperature measurements in the range of several hundred degrees.

Partners:

AOS GmbH

General Electric Global Research Europe

MTU Aero Engines GmbH

Xiton Photonics GmbH

|

|

|

|

|

|

HiBi

Funding:

Bundesministerium für Bildung und Forschung (BMBF)

Grant number:

|

|

|

Polarization Maintaining FBG Sensors (HiBi)

Period: 2010-2013

Titel: Fiber Bragg sensor technology with polarization maintaining fiber wave guides

Abstract: Birefringence effects have a negative influence on the sensor performance of FBG in single mode fibers, especially in presence of transversal loads. FBG in polarization maintaining fibers help to avoid these effects.

Partners:

General Electric Global Research Europe

Hottinger Baldwin Messtechnik GmbH

|

|

|

|

|

|

APE

Funding:

Bundesministerium für Bildung und Forschung (BMBF)

Grant number:

|

|

|

Application and Precision Enhancement of FBG-Sensors

Period: 2006-2009

Titel: : Application and precision enhancement of FBG sensor technology

Partners:

Kayser-Threde GmbH

AOS GmbH

European Aeronautic Defence and Space (EADS)

|

|

|